This is a test of the "site alert message system".

This is a test of the "site alert message system". 123

Motorization Options

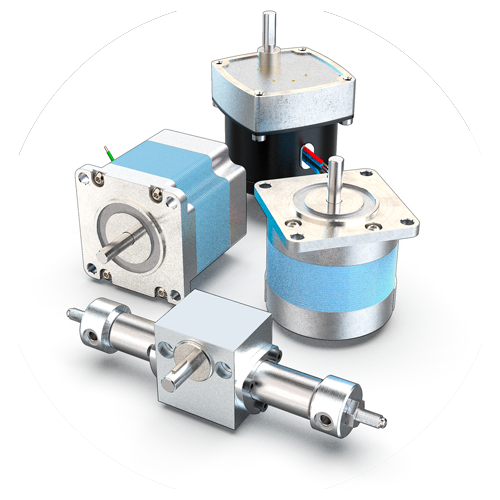

Linear & Rotary Feedthrough Motorization

AGP offers three actuator motorization options, which are ideally suited for the remote actuation of its precision linear and rotary motion instruments. Two DC powered stepper motor options—one for low and the other for high torque applications, one AC powered synchronous gear motor solution for low-speed continuous rotary applications, and one pneumatic rack-and-pinion linear-to-rotary actuator used for 90° 'flip motion' actuation when mounted to an AGP rotary motion feedthrough—commonly used for in-vacuum shutter actuation.

- Option-11, DC stepper motor, 75 oz-in holding torque, NEMA 23 frame

- Option-12, DC stepper motor, 170 oz-in holding torque, NEMA 23 frame

Note: Both DC stepper motor options offer resolutions of 200 steps per revolution, and can be operated in full, half, and micro-step increments in angles of 1.8°, 0.9°, and fractions thereof respectively. - Option-21, Synchronous AC motor, 126 oz-in torque, Geared for 10 RPM output

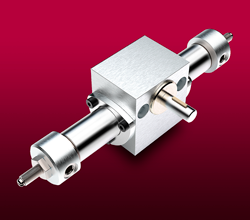

- Option-31, Pneumatic rack-and-pinion linear-to-rotary actuator, CW and CCW '90° flip motion' (only used with rotary feedthroughs).

Motor options must be factory-fitted and tuned with the standard linear or rotary motion feedthrough on which they are to be mounted. These options are ideally suited for use with AGP’s 1, 2, or 4 inch linear travel and/or continuous motion rotary feedthroughs. Custom solutions are available on request.

Please note that AGP does not currently offer motor drive and control options, as most customers choose to use their existing in-house setups. Also, there are a considerable number of third-party control solution providers to choose from in today's automation market.

Features

- DC Stepper Motor, Low Torque

- DC Stepper Motor, High Torque

- AC Motor, Synchronous Geared

- 90° Pneumatic Actuator

Specifications1

| Option 11 | DC Stepper LT |

| Frame Size | □ 2.24 in |

| Shaft Diameter | Ø .250 in |

| Weight | 1.5 lb |

| Torque | 75 oz-in |

| Steps per Revolution | 200 |

| Voltage, Input | 7 VDC |

| Current, Input | 0.7 A |

| Leads | 6 |

| Option 12 | DC Stepper HT |

| Frame Size | □ 2.24 in |

| Shaft Diameter | Ø .250 in |

| Weight | 1.7 lb |

| Torque | 170 oz-in |

| Steps per Revolution | 200 |

| Voltage, Input | 4.2 VDC |

| Current, Input | 1.4 A |

| Leads | 6 |

| Option 21 | AC Synchronous |

| Frame Size | □ 2.38 in |

| Shaft Diameter | Ø .250 in |

| Weight | 3 lb |

| Torque | 126 oz-in |

| Speed, Output | 10 RPM |

| Voltage, Input | 115 VAC |

| Power, Input | 7.5 W |

| Leads | 4 |

| Option 31 | Pneumatic |

| Size | 1.45x5.5 in |

| Shaft Diameter | Ø .250 in |

| Weight | 0.5 lb |

| Torque, per PSI | 1.088 oz-in |

| Rotation, Maximum | 90° |

| Rotation, Minimum | 30° |

| Pressure, Max. Air | 150 PSI |

| Line, Air Supply | Ø .125 in |

| Solenoid, 4-Way | 115 VAC |

| 1/8" Fitting Ports | #10-32 UNF |

| Notes |

- To see detailed specifications for each motor option listed, click the specific 'motorization option tile' at the top of this page.