This is a test of the "site alert message system".

This is a test of the "site alert message system". 123

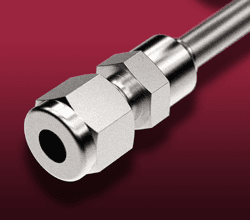

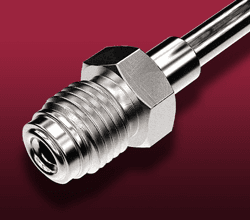

Swagelok + VCR General Service Fluid Feedthroughs

Gas, Liquid, Fluid General Service Feedthroughs

General service fluid feedthroughs are used to deliver gas and/or cooling liquids, such as tap-water, into high (HV) and ultrahigh (UHV) vacuum systems. Feedthroughs are available in single or dual tube configurations, with 1/8 or 1/4 inch tube diameters. Feedthroughs are terminated with Swagelok standard compression (swaging) fittings, or VCR metal-gasket-fitted, ultrahigh-vacuum-rated fittings.

The Swagelok® fittings products a demountable, gas-tight cold-formed (swaged) mechanical joint between a tube's OD and the ferrules housed inside each fitting. Tube finish, temper, and wall thickness are all critical parameters for making reliable, gas, and vacuum-tight seals.

The VCR fittings are zero-clearance, demountable UHV compatible mechanical joints produced by crushing a deformable metal gasket between two mating and polished fitting gland faces. Fitting gland finish, and metal gasket temper are critical parameters for making reliable, gas, and ultrahigh vacuum seals.

These are general purpose, non-cryogenic, tube feedthroughs used for gas and/or fluid coolant delivery into high and ultrahigh vacuum systems.

| Material | |

|---|---|

|

|

| Vacuum Range | |

|---|---|

|

1x10-13 Torr 1x10-8 Torr |

| Temperature Range | |

|---|---|

|

|

| * Overall assembly ratings must be adjusted to that of the lowest-rated component. |